Here are some specifications for Monel 400:

Chemical Composition (approximate percentages):

Nickel (Ni): 63%

Copper (Cu): 28-34%

Iron (Fe): 2.5%

Manganese (Mn): 2%

Carbon (C): 0.3%

Silicon (Si): 0.5%

Sulfur (S): 0.024%

Physical Properties:

Density: 8.80 g/cm3 (0.318 lb/in3)

Melting Point: 1300-1350°C (2370-2460°F)

Electrical Conductivity: 34% of copper

Mechanical Properties (Typical Values):

Tensile strength: 550-750 MPa (80,000-109,000 psi)

Yield strength: 240 MPa (35,000 psi)

Elongation: 40%

Corrosion Resistance:

Excellent resistance to corrosion in various environments, including seawater, acidic and alkaline solutions, sulfuric acid, hydrofluoric acid, and many other corrosive substances.

Common Applications:

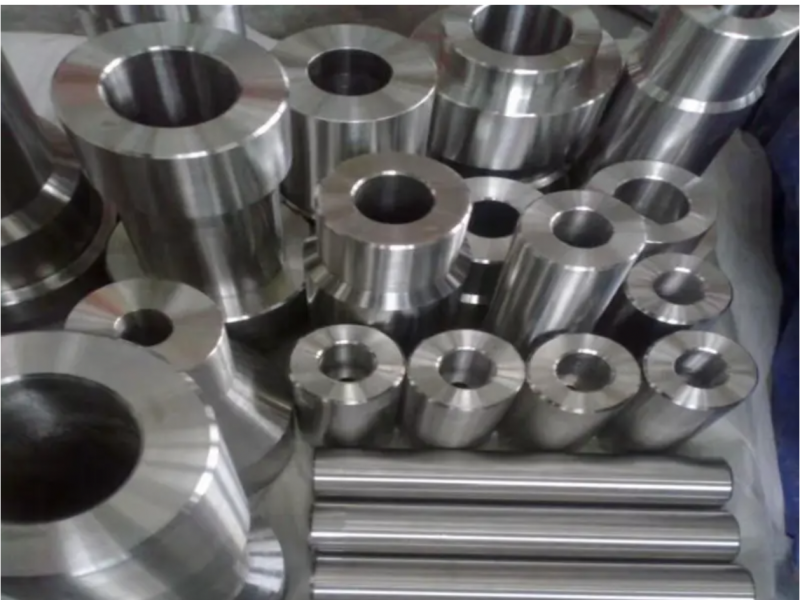

Marine engineering and seawater applications

Chemical processing equipment

Heat exchangers

Pump and valve components

Oil and gas industry components

Electrical and electronic components

It's important to note that these specifications are approximate and can vary depending on specific manufacturing processes and product forms (e.g., sheet, bar, wire, etc.). For precise specifications, it's recommended to refer to the manufacturer's data or relevant industry standards.

Monel K500 is a precipitation-hardenable nickel-copper alloy that offers exceptional corrosion resistance, high strength, and good mechanical properties at both room and elevated temperatures. Here are some of the specifications for Monel K500:

Chemical Composition:

- Nickel (Ni): 63.0-70.0%

- Copper (Cu): 27.0-33.0%

- Aluminum (Al): 2.30-3.15%

- Titanium (Ti): 0.35-0.85%

- Iron (Fe): 2.0% maximum

- Manganese (Mn): 1.5% maximum

- Carbon (C): 0.25% maximum

- Silicon (Si): 0.5% maximum

- Sulfur (S): 0.010% maximum

Physical Properties:

- Density: 8.44 g/cm³ (0.305 lb/in³)

- Melting Point: 1300-1350°C (2372-2462°F)

- Thermal Conductivity: 17.2 W/m·K (119 BTU·in/h·ft²·°F)

- Electrical Resistivity: 0.552 μΩ·m (345 μΩ·in)

Mechanical Properties (at room temperature):

- Tensile Strength: 1100 MPa (160 ksi) minimum

- Yield Strength: 790 MPa (115 ksi) minimum

- Elongation: 20% minimum

Corrosion Resistance:

- Monel K500 exhibits excellent resistance to various corrosive environments, including seawater, brine, acids, alkalis, and sour gas environments containing hydrogen sulfide (H2S).

- It is particularly resistant to pitting, crevice corrosion, and stress corrosion cracking (SCC).

- The alloy can be used in both reducing and oxidizing conditions.

Applications:

- Marine components, such as propeller shafts, pump shafts, valves, and fasteners.

- Oil and gas industry equipment, including pumps, valves, and high-strength fasteners.

- Springs and bellows in high-pressure and high-temperature environments.

- Electrical and electronic components.

- Aerospace and defense applications.

These specifications are general guidelines, and specific properties may vary depending on the product form and heat treatment. It is always recommended to consult the manufacturer or supplier for detailed technical information regarding Monel K500.

Monel 400 and Monel K-500 are both alloys in the Monel series and have similar chemical compositions, primarily consisting of nickel and copper. However, there are some key differences between the two that differentiate their properties and applications.

Chemical Composition: Monel 400 is composed of approximately 67% nickel and 23% copper, with smaller amounts of iron, manganese, and other elements. On the other hand, Monel K-500 has a composition of about 65% nickel, 30% copper, 2.7% aluminum, and 2.3% titanium, with trace amounts of iron, manganese, and silicon. The addition of aluminum and titanium in Monel K-500 gives it enhanced strength and hardness compared to Monel 400.

Strength and Hardness: Monel K-500 is known for its high strength and hardness, which can be achieved through precipitation hardening. In contrast, Monel 400 is relatively softer and has lower yield and tensile strength.

Corrosion Resistance: Both Monel 400 and Monel K-500 exhibit excellent corrosion resistance in various environments, including seawater, acids, alkalis, and other corrosive mediums.

Applications: Monel 400 is commonly used in applications such as marine engineering, chemical processing, and heat exchangers, due to its good corrosion resistance and high thermal conductivity. Monel K-500, with its superior strength and hardness, finds applications in pump and valve components, fasteners, springs, and other parts requiring high strength and corrosion resistance in harsh environments.

Overall, the choice between Monel 400 and Monel K-500 depends on specific requirements for strength, hardness, and corrosion resistance in a given application.

Post time: Jul-24-2023